|

On January 28, Eagle Robotics received an emergency email. Georgia FIRST had just received notice that the venue that had been reserved for the FTC State Championship was no longer available. With only sixteen days left until competition, the situation looked grave. Georgia FIRST wanted to know if it would be possible to hold the event at Mount Paran Christian School, the home of Eagle Robotics, and Team 7373.

The inquiries that followed started an avalanche of meetings, organizers, administrators, FIRST representatives, and Team 7373 members. On February 2, Mount Paran Christian School and Team 7373 made it official. The State Championship would have a home at MPCS. Then the real "Cascade Effect" began as the Eagle Nation went into high gear. High School Robot Parents, Middle School Robot Parents, Beta Club, Key Club, and National Honor Society all made an appeal to get out an Eagle army of volunteers. By far, this was the pinnacle of both outreach and connection for Team 7373's season. We made an impact on every qualifying team in the states of Tennessee, Alabama, and Georgia. We also made an enormous impact in introducing FIRST and its ideals to our school and local community. We hosted guests from local engineering businesses, and interacted with the media. The event was documented in the Marietta Daily Journal on Monday, February 17th. In addition to hosting, we were competitors ourselves that day, finishing up as a finalist in the runner-up alliance and garnering the Connect Award. The fruit of a year's worth labor, the events documented below were all part of an initiative to win that award. Team 7373 wishes to express its deep appreciation of so many people and organizations that have made this competition season and the State Championship possible. If it were not for you, none of this would have been possible! We honor you by the image on left. Thank you so very much! |

Team 7373 Takes a Guided Tour of Omni, International, The Homogenizer Company

|

|

Team 7373 was honored to visit Omni International, "The Homogenizer Company," on January 23. Owner Karl Jahn, and Engineering Manager Spencer Smith created a tour experience that allowed us to follow the engineering process from concept to finished product. We visited multiple regions/divisions of the business including Engineering, Sales, Production, Quality Control, and the Testing Laboratory.

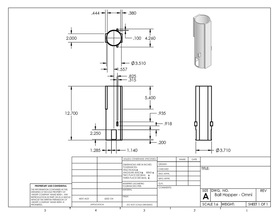

Omni makes homogenizers, devices that mix or blend materials. Not your average blender, though. We're talking breaking materials into particles so small they are on the order of the size of clusters of molecules, or even individual molecules. Omni creates homogenizers based on several technologies, including mechanical shear, ultrasonic, and bead mill. They also have automated robotic systems that incorporate homogenization into high-throughput testing. Homogenization is required for many industries. The food, pharmaceutical, medical, biotech, and chemical industries are just a few. From DNA testing to fluoride testing in toothpaste; from cellular organelle extraction to paints; from facial creams to forensic testing, homogenization is a critical step in the process of manufacturing or research of many industries. Team 7373 witnessed prototypes and functional models of an invention in the "proof of concept" stage. We visited with Trey Hancock, Senior Engineer, who showed us CAD simulations of the motion of the prototype. Spencer explained the role of 3D printing to the creative process at Omni. We were particularly fascinated with the way 3D printing impacts both prototyping and manufacturing at Omni. T.J. Gray, Automation Engineer, showed us video of many automated processes he worked on, and explained a table full of prototypes, motors, and control circuit boards. Spencer and Karl showed us through the Quality Control area. Spencer showed the Bead Ruptor 24 in action, and Karl showed us the original homogenizer that started it all for Omni. Chase Campbell, an engineering intern from Southern Polytechnic State University, reflected on the benefits of working at Omni. Our tour concluded with a discussion of the nature of running an engineering-based business, and the need to "learn how to learn" problem-solving techniques that exceed today's questions and lead into innovations in technology for tomorrow. We want to extend our heartfelt thanks to Karl Jahn and Spencer Smith for helping our team with a 3D print job. When our Makerbot printer broke during an all-night print attempt, Omni stepped up and printed the canister-style hopper our team designed in PC-ABS on their Stratasys Fortus 400mc printer. Our CAD drawing of the canister can be seen on the left. The slideshow on the left shows our part printing. This keeps us viable for competition on January 31st, not to mention the "wow" factor of seeing a part we had designed being printed on an industry-grade printer! If you're a fan of Eagle Robotics look for this part on the robot on January 31st. Finally, we'd like to recognize the gift of the 3D printed badge that Omni provided for us. The badge is a nonfunctional part, designed by Team 7373 that serves as a sort of "hood ornament" for the robot. It was created on a Stratasys Objet 30 Pro printer in Veroclear RGD810 material, and is 2 inches wide. Look for it as well on the finished robot! See the video on the Object 30 Pro on the left. Thanks, Omni, for investing in us! We learned a lot from you, and so appreciate your investment of time in educating and assisting our team! |

Team 7373 Elated at Progress of Rookie FLL Eagle Robotics Performance

Team 7373 Efforts to Increase STEM Awareness Results in Increased Engineering Summer Camp Offerings

|

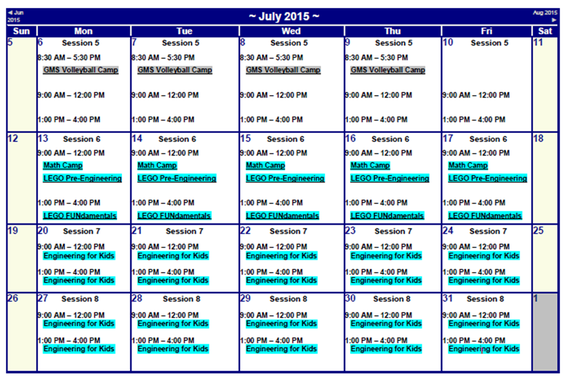

The continued effort to mentor students in First LEGO League middle school teams at Mount Paran Christian School has resulted in a grass-roots firestorm of interest and demand for more engineering and STEM classes, workshops, camps, and competitions.

As of this release, the following summer camp offerings have been announced. Believe it or not, there are rumors of even more offerings! The MPCS Summer Camp webpage can be accessed here. |

Mad Scientist Camp (Kindergarten-5th)

The Mad Scientist summer camp will give kids the opportunity to learn about science through an interactive and hands-on activity based camp. Not only will we create crazy experiments, we will learn the science behind it. Crazy Chemistry, Fun with Physics, CSI, MATTER MONSTER, Dry Ice 101, and more.

Math Camp (3rd - 5th)

Want to have a “fraction-packed” week? We will have “sum” fun - you can “count” on it! This week will provide students with a review of basic math skills in the areas of place value, multiplication, division, fractions, and measurement. The week is designed for any student who could benefit from summer math review (or for those who just love math!). Each day will focus on a specific math topic which will be taught through whole group games, technology, and hands-on activities.

LEGO Pre-engineering (Kindergarten-3rd)

Let your imagination run wild with tens of thousands of LEGO®! Build engineer designed projects such as boats, bridges, mazes and motorized cars, and use special pieces to create your own unique design! Explore the endless creative possibilities of the LEGO® building system with the guidance of an experienced Play-Well instructor. This is an ideal way to prepare young builders for the challenge of Engineering FUNdamentals.

LEGO FUNdamentals (3rd-7th)

Power up your engineering skills with Play-Well TEKnologies and tens of thousands of LEGO®! Apply real world concepts in physics, engineering, and architecture through engineer-designed projects such as archbridges, skyscrapers, motorized cars, and the Battletrack! Design and build as never before, and explore your craziest ideas in a supportive environment. An experienced instructor will challenge new and returning students to engineer at the next level.

Engineering for Kids (PK-2nd)

Junior robotics animals (WeDO), Junior aerospace, Junior robotics - amazing mechanixsms, Junior Mechanical Engineering

Engineering for Kids (3rd-7th)

Survivor - Engineer's Cove, Video Game Design - Platform Games, Momentum Madness - Design and Build Vehicles for Speed and Safety, Video Game Design - Racing Games

Engineering the CO2 Dragster (7th-8th)

Hosted by Learning Through Making, this middle school level engineering camp will guide you through the process of designing and building a dragster powered by compressed gas. The camp features a visit to Southern Polytechnic State University's wind tunnel!

The Mad Scientist summer camp will give kids the opportunity to learn about science through an interactive and hands-on activity based camp. Not only will we create crazy experiments, we will learn the science behind it. Crazy Chemistry, Fun with Physics, CSI, MATTER MONSTER, Dry Ice 101, and more.

Math Camp (3rd - 5th)

Want to have a “fraction-packed” week? We will have “sum” fun - you can “count” on it! This week will provide students with a review of basic math skills in the areas of place value, multiplication, division, fractions, and measurement. The week is designed for any student who could benefit from summer math review (or for those who just love math!). Each day will focus on a specific math topic which will be taught through whole group games, technology, and hands-on activities.

LEGO Pre-engineering (Kindergarten-3rd)

Let your imagination run wild with tens of thousands of LEGO®! Build engineer designed projects such as boats, bridges, mazes and motorized cars, and use special pieces to create your own unique design! Explore the endless creative possibilities of the LEGO® building system with the guidance of an experienced Play-Well instructor. This is an ideal way to prepare young builders for the challenge of Engineering FUNdamentals.

LEGO FUNdamentals (3rd-7th)

Power up your engineering skills with Play-Well TEKnologies and tens of thousands of LEGO®! Apply real world concepts in physics, engineering, and architecture through engineer-designed projects such as archbridges, skyscrapers, motorized cars, and the Battletrack! Design and build as never before, and explore your craziest ideas in a supportive environment. An experienced instructor will challenge new and returning students to engineer at the next level.

Engineering for Kids (PK-2nd)

Junior robotics animals (WeDO), Junior aerospace, Junior robotics - amazing mechanixsms, Junior Mechanical Engineering

Engineering for Kids (3rd-7th)

Survivor - Engineer's Cove, Video Game Design - Platform Games, Momentum Madness - Design and Build Vehicles for Speed and Safety, Video Game Design - Racing Games

Engineering the CO2 Dragster (7th-8th)

Hosted by Learning Through Making, this middle school level engineering camp will guide you through the process of designing and building a dragster powered by compressed gas. The camp features a visit to Southern Polytechnic State University's wind tunnel!

Team 7373 Sponsors STEM Workshop - "Design Thinking"

|

Team 7373 is proud to sponsor a 3D technology workshop entitled "Design Thinking".

This three-day workshop in design and additive manufacturing is presented by the Learning Through Making group, a nonprofit organization of Georgia Tech PhDs, whose mission is to introduce STEM training to as many students as possible. The workshop will focus on the process of design thinking, and will offer students the opportunity to create in the 3D environment and print to 3D printers. The event will serve as the climax of Discover E: Engineers Week, which also includes Discover E: Girl Day. Team 7373 is making a concerted effort to reach out to female students in this event. The event runs Thursday, February 26 to Saturday, February 28. |

Team 7373 Featured in COBB in focus magazine

|

Team 7373 was contacted in December 2014 by COBB in focus magazine. The magazine was doing an article in its January/February issue entitled "Sparking an Interest" which was dedicated to STEM training in Cobb County. Team 7373 provided COBB in focus quotes, photographs, and access to this website to provide documentation of our history, projects, awards, outreach, and values.

The article focuses on the need to prepare students for STEM jobs, the specialized training that requires, and the creative ways Cobb County schools have found to bring this about. A large portion of the article was dedicated to the FIRST programs. Team 7373's 2014 robot was pictured on page 15, and Mount Paran Christian School placed an advertisement in the article on page 13. The magazine's readership is 58,000, so we consider this a pretty cool way of reaching out to the community! |

Your browser does not support viewing this document. Click here to download the document.

|

A Return to Delta Sigma - A Finished Robot Ships to Serve Freightliner® Assembly Line

|

|

Delta Sigma finished up their project for Freightliner. We had seen the project in progress in October, but when it was completed, we were invited back to see it fully functional and automated. We showed up on Wednesday, January 7th, and Delta Sigma delivered! We were impressed and full of questions as we watched the system run a program to prepare the roof of a Freightliner truck for attachment to the body. The system was then delivered to the client, and is now installed and building trucks!

Thanks again to Roger Richardson, who has gone out of his way to help educate our team! |

Team 7373 reaches out to Walton Ridenour Adventure Center After-school program

|

On Friday, November 7, Team 7373 set up a booth at the Region 1 play-in football game tailgate party on the campus of Mount Paran Christian School. The purpose was manifold: to reach out to our community in teaching what Team 7373 does, what FIRST is, and how robots work, and to raise funds to service our season. Our ministry partners for the evening were the children from the Walton Apartment Ridenour Adventure Center After-school program. Students enjoyed free hot chocolate, watching the Rhino XR-4 trainer robot (which team member Nick Weaver used to retrieve baked goods from the bake sale adjacent to it), and dancing the "Macarena" and "Cotton-Eyed Joe" with the Vex Clawbot. Students enjoyed learning to drive the Clawbot as well.

|

Team 7373 Takes Tours for MFG Day

|

|

MFG DAY addresses common misperceptions about manufacturing by giving manufacturers an opportunity to open their doors and show, in a coordinated effort, what manufacturing is — and what it isn’t. By working together during and after MFG DAY, manufacturers will begin to address the skilled labor shortage they face, connect with future generations, take charge of the public image of manufacturing, and ensure the ongoing prosperity of the whole industry.

Supported by a group of industry sponsors and co-producers, MFG DAY is designed to amplify the voice of individual manufacturers and coordinate a collective chorus of manufacturers with common concerns and challenges. The rallying point for a growing mass movement, MFG DAY empowers manufacturers to come together to address their collective challenges so they can help their communities and future generations thrive. In celebration of MFG day, Team 7373 visited two local businesses: Delta Sigma Company, and Win-Tech, Inc. |

|

|

A Foray into Engineering at Delta Sigma CompanyOn Thursday, October 23, members of the Foundations of Engineering class, The Concepts of Engineering class, and Team 7373 Eagle Robotics attended a tour of Delta Sigma Company, in Kennesaw, Georgia.

Delta Sigma Company specializes in developing systems and tools to automate large, complex, precision assembly and manufacturing processes. Owner Roger Richardson hosted the tour himself, demonstrating to students DSC’s award-winning ProjectionWorks technology. ProjectionWorks is revolutionizing semi-automated assembly lines by streamlining processes that once took much longer to accomplish, and potentially eliminating a great degree of human error. The tour concentrated on engineering at the project and systems level, with projects spanning the gamut from instruction delivery for assembling the F-35 fighter jet, to big-rig aerodynamics; from fiber optic innovation to automation of the retrieval, preparation, and allocation of parts for aircraft assembly. We thank Roger and his crew for spending time with us and for inspiring and investing in our students. |

Remembering Win-TechCheck out how the world's most complicated watch is put together. At a cool $2.5 million, it's pretty spectacular. Watch how precise each little piece must be as they assemble this right before your eyes! Click the image below to see it being assembled. Enjoy!

|

A Visit to Win-Tech, Inc., a Precision Machine ShopOn Friday, October 24, members of the Foundations of Engineering class, The Concepts of Engineering class, and Team 7373 Eagle Robotics attended a tour of Win-Tech, Inc., in Kennesaw, Georgia.

Win-Tech, Inc. is an AS9100-certified custom machine shop, making parts per customer specification. They feature computer-controlled technology with 4-Axis capability, in addition to a complete range of conventional equipment. Students participated in a full-shop tour hosted by President Dennis Winslow and Shop Manager John Hudson and watched a video presentation featuring interviews with Win-Tech employees about how they got started in manufacturing. Student favorites were the Large Capacity CNC Vertical Mill, the Water Jet Machining Equipment, and the Wire Burn EDM machine. We’d like to extend our thanks to Win-Tech President Dennis Winslow, Shop Manager John Hudson and his crew, and Allison Krache Giddens for making this an informative and educational opportunity for our budding inventors, designers, manufacturers and engineers! Also, thanks for the Facebook shout-out! |

Team Captain Brian Park receives patent for robotics work

|

|

On August 2, 2014, I was delighted to receive the culmination of two years of research and development. I was notified that I received a patent on a project that had captured my imagination for some time. I’m not at liberty to reveal the entirety of the process, but it is about a robot that can mimic certain vertebrates some times, but act like an invertebrate at others. I gained my inspiration from an oceanic creature called the mimic octopus. I noticed that the mimic octopus could walk upright under water on two of its eight legs. As it does, it coils six of its legs, and with the other two it “walks” or “jumps”. Inspired by this idea, I took the concept into the land of biomimetic robotics. Using my seven years of experience in robotics and some specific training in patent writing through the Seoul Metropolitan Office of Education, I began to prepare the patent. I drew blueprints of my robot, wrote out specific claims, and performed research on ideas. In August I received the fruit of my labor. Through this patent project I was able to use my mathematics, science, and engineering abilities that I enjoy so much. I would like to encourage every student to strive to understand that the knowledge that we learn can only blossom when it is used.

|

2014 graduate Gabriel Bland receives manufacturing scholarship

|

A routine assignment in an engineering class led to scholarship money for Gabe Bland. He recounts here his recollection.

During my Foundations of Engineering and Technology class at Mount Paran Christian School, my instructor, Mr. Smith, gave an assignment in which every student had to research and find an engineering-based scholarship. In that research I found that the Fabricators & Manufacturing Association, Intl., had a foundation by the name of Nuts, Bolts, & Thingamajigs. That foundation offered a scholarship called the NBT Trade School, Community or Technical College Scholarship. I applied and was awarded $1,500 and a year-long license of SolidWorks© CAD software. I am very grateful to the FMA and NBT for this blessing.

Gabe recently shared this video that he made for one of his classes at SPSU |

2014 graduate Jacob Ramsey reflects on his Executive Internship at GTRI/Lockheed Martin

Throughout his senior year at Mount Paran Christian School, Team 7373 member Jacob Ramsey participated in a year-long Engineering Executive Internship at Georgia Tech Research Institute's Lockheed Martin facility. He reflects here on what he experienced and what he learned.

Team 7373 visits Georgia Tech for National Robotics Week 2014

|

April 5-13 was National Robotics Week 2014, the fifth annual celebration of all things automated. More than two hundred events were planned nationwide to showcase the growing importance of robots in the United States.

Georgia Tech’s Institute for Robotics & Intelligent Machines (IRIM) hosted its own event on April 8, featuring tours of robotics labs on campus. Team 7373 attended the event, and examined numerous robots of all kinds: land-based, underwater vehicles, and airborne robots. The kind researchers from Georgia Tech Research Institute (GTRI) manned each display and answered countless questions. |

|

Video clips of this event:

1. Tai Chi anyone?

2. Baxter wrestles with chickens... I think

3. Baxter again

4. Walking through the exhibits

5. The CSOT: a spatial cognitive radio testbed

6. Aerial Tracking with Ground Assist

1. Tai Chi anyone?

2. Baxter wrestles with chickens... I think

3. Baxter again

4. Walking through the exhibits

5. The CSOT: a spatial cognitive radio testbed

6. Aerial Tracking with Ground Assist

Team 7373 Sponsors events for eWeek 2014

February 16-21 was National Engineers week, or eWeek. Members of Team 7373 participated in events at Mount Paran Christian School pertaining to learning about the engineering field.

- Members of the Foundations of Engineering and Technology Class had a private session with Lockheed Martin Staff Engineer John Quarles. Topics included an overview of the discipline, advice on high school and career planning, job market projections, college selection, and insider advice from a hiring recruiter.

- Team members from the Foundations of Engineering and the Concepts in Engineering class sponsored the after-school "Introduce a Girl to Engineering Day" event with Transformance Software Engineer Sandy Quarles.

- Team members sponsored the "Discover Engineering: Let's Make a Difference" middle school exploration with John Quarles. Each event focused on each separate target audience. Topics for the first session included benefits of a female approach to engineering, balancing career, family life, and faith, making a difference in the world, and unique opportunities in engineering available to females. The middle school event included a hands-on challenge where students had to invent a device of three sequential machines that could launch a ping pong ball a minimum of a seven foot range.

STE+A+M = Science, Technology, Engineering, ARTS, and Mathematics

Robotics team members of the AP Physics B class enjoyed a two-day in-house field trip to the Murray Arts Center at Mount Paran Christian School.

|

The first day was guided by Technical Director David Foster and Assistant Technical Director Jaime Mellars, and focused on the physics of the Kristi Lynn Theatre. Acoustics topics ranged from room geometry to surface treatments, electronic amplification to room tuning (white noise, pink noise), sound levels, microphone equalization for soloists and company, etc. Students explored the mechanics of the 20+ arbors that serve the rigging for the orchestra shell, sets, backdrops, and actor fly-rigging. Students investigated the hydraulic lift for the orchestra pit and the various types of optics involved in the intelligent light systems.

Day two was spent with Studio Manager Brent Maloney in the Murray SoundLab recording studio. Students learned how to isolate sound in booths and route it to the mixing board, how to tune microphones on a drum set so that the sound is recorded in phase, and how to utilize both the sound board itself and ProTools software to manipulate sound envelopes for a professional recording. |

|